How manufacturers and distributors are responding to post-pandemic labor shortages

How manufacturers and distributors are responding to post-pandemic labor shortages

Manufacturers and distributors faced with exploding demand or shortages, 2020 was a difficult year. The skilled worker shortage will not go away as markets, factories, warehouses, offices, and offices expand.

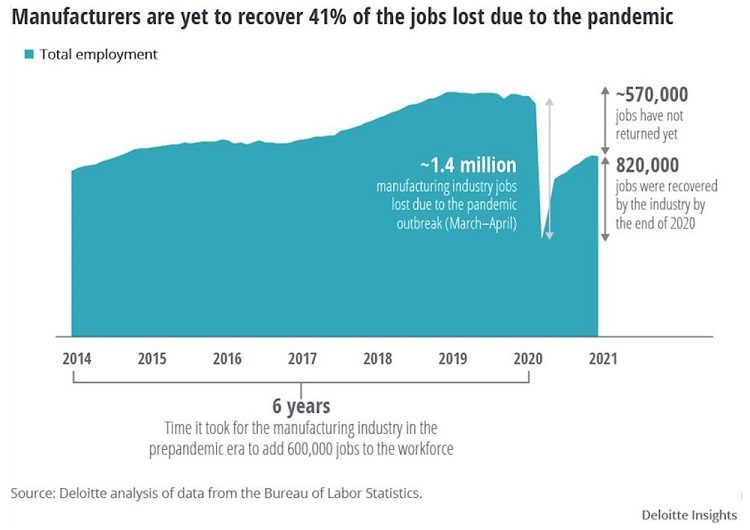

According to June 2021 US Bureau of Labor Statistics data, manufacturing added 15,000 jobs but employment is still down by 481,000 from the February 2020 number. Transportation and warehouse added 11,000 jobs, but the number is still 94,000 less over that same period. Deloitte projects that the annual loss in manufacturing GDP could reach $454 billion if the industry cannot fill the anticipated jobs by 2028.

[Source]

Whatever the root causes, the shortage of labor is forcing employers to be creative in their hiring practices. In this post, we will discuss how B2B companies have changed their hiring processes and invested in employees to meet the challenges of talent shortages. We will also discuss how to use technology to improve productivity and streamline work processes.

Faced with an uncertain job market

University of California at San Diego economist Jeffrey Clemens believes the pandemic caused changes in the way many workers view their employment. He stated in a Washington Post interview that the pandemic broke many links between workers and pre-pandemic employers, and that it brought about a wide range of factors that made it less appealing for people to work in the same jobs they had previously.

This is a problem, as employers are unable to fill entry-level production jobs, let alone highly skilled, despite a near record number of job openings.

Our products:

MSI multi-source-inventory-management-system

[Source]

There are many reasons. For millennials, distribution and manufacturing jobs are not top choices. These industries are seeing a rapid decline in their workforce, which is reducing the overall talent pool and increasing the skills gap.

Industrial hiring managers say that it's 36% harder to find talent now than in 2018, even though the unemployment rate is much higher today. They often have to compete for skilled talent in the construction, technology, and raw materials industries, which offer higher salaries.

Manufacturers need to immediately put in place strategies to retain seasoned, skilled, and experienced workers while actively training and acquiring new talent.

How can manufacturers address the problem of a shortage in their workforce?

The COVID-19 pandemic had a profound impact on the employment situation of distributors and manufacturers. Manufacturers are inventive and some brands have already developed unique ways to reduce worker shortages. They employ three strategies: they look internally, increase compensation and invest in technology.

1. 1. Look for internal talent and pre-vetted candidates

Manufacturers historically used contract employees and temporary workers to address increases due to higher demand, seasonal changes, or new product lines. This is because it can be costly and time-consuming to search for skilled positions in a specific industry. It's best to outsource this task to a temp agency. Staffing agencies save time by screening and qualifying temporary and contractual workers.

Staffing agencies are the best solution for larger businesses, especially seasonal ones. This is especially true for businesses that warehousing is an expensive, recurring operation expense that makes up a substantial portion of their budget.

Airhead needed to fill 12 positions throughout the company during busy season. They turned to a talent agency for help in finding skilled warehouse workers.

An existing relationship with staffing agency Gigsmart allowed Airhead to tap into 2,000 skilled local workers. Gigsmart provided many gig, temp and contract positions to fill Airhead's needs faster. Airhead was also provided with an app that allows them to post gigs whenever they need it.

Airhead found this a great strategy. They could focus on other tasks such as interviewing candidates, managing payroll, and sifting through the applications. Airhead can now focus its HR department to more strategic, valuable recruiting initiatives by outsourcing routine tasks.

https://www.connectpos.com/best-shopify-loyalty-programs-in-2021/

https://www.connectpos.com/why-should-online-stores-have-the-wish-list-function/

https://www.connectpos.com/best-magento-2-reward-point-extension-in-2021/

https://www.connectpos.com/woocommerce-customers-and-their-omnichannel-examples/

https://www.connectpos.com/top-pos-systems-for-retail-businesses/

It's the relationships built over time that make it possible for businesses to succeed in the startup or small business environment. Alpeter admits that there has always been a shortage of operational talent in startups. "People who are knowledgeable about their field are highly sought after and often earn more than those with smaller budgets."

Smaller manufacturers are also at risk from the same risks. These include driver shortages and competition for warehouse workers. Rising commodity prices and rising transportation costs mean that there are fewer resources available for sign-on bonuses and high salaries.

The solution? Alpeter believes that you need to look inwards. Alpeter believes you should look inwards.

2. 2.Invest in your employees and sweeten your job offers

Amazon holds nearly half the eCommerce market. It is also a leader in warehouse labor rates and benefits. According to Supply Chain Dive, if competitors want to attract talent in high-demand roles, they must raise salaries by as much as 3.5%. This may work for certain distributors. However, other companies are coming up with creative solutions.

Hunter Brown is with Visible Supply Chain Management, an end-to-end fulfillment solution that aligns shipping solutions with customer goals.

Hunter Brown is with Visible Supply Chain Management, an end-to-end fulfillment solution that aligns shipping solutions with customer goals.Visible Supply Chain Management launched a program in Spring 2020 that offered higher hourly wages and full benefits for workers' first days. Visible wanted to test and see if traditional methods of raising salaries were more effective than those used by the company. Visible began offering free lunch and breakfast, which resulted in increased employee retention.

Another manufacturer was facing severe talent shortages at its Cincinnati facility and desperately needed to fill vacant positions. They were able to handle more applicants with one unique strategy.

Eric Wellinghoff is CMO at Nehemiah Manufacturing, which produces consumer products such as washing machine cleaners, cleaning products, and dryer balls.

Eric Wellinghoff is CMO at Nehemiah Manufacturing, which produces consumer products such as washing machine cleaners, cleaning products, and dryer balls.Nehemiah is able to maintain a 100% turnover rate, which is a common problem for their competitors. According to Wellinghoff, Nehemiah has a turnover rate of around 15% and the majority its employees stay with them for longer than five years.

However, such success did not happen overnight. Nehemiah employed a staffing agency to help him hire ex-felons during the 2008 recession. After much thought, Richard Palmer and Dan Meyer decided to give it another shot. The Second Chance program has expanded to include employees with substance abuse or past problems.

The numbers speak for themselves: Nehemiah is a top 20 most profitable manufacturers and earns $60M in revenue. About 85% of the 110 workers in the warehouse and production operations are Second Chance employees. The program was so successful that it gave birth to a new initiative, the Beacon of Hope Business Alliance. The non-profit has shared Second Chance best practices with other organizations since 2015 and inspired them to adopt the second chance philosophy.

3. Technology and automation can be augmented

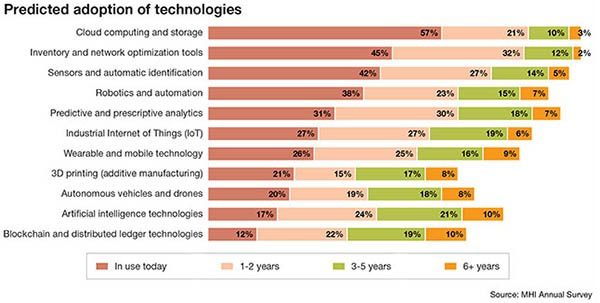

The pandemic was a catalyst for manufacturers to invest in digital technology. It's no surprise that according to the 2021 MHI Annual Industrial Report, manufacturers are increasing investment into digital tools to manage networks, cloud data, inventory, as well as digital and physical automation.

Technology is the solution for manufacturers, distributors, supply chain leaders, and others who want to increase operational efficiency, improve resilience, unlock new growth opportunities, and maximize operational efficiency. Technology can help reduce labor-related problems by using automation and robotics technology.

Travis Turner is Director of Business Development eCommerce and Supply Chain for Hire Dynamics, a warehouse talent recruitment firm with over 300 clients.

Travis Turner is Director of Business Development eCommerce and Supply Chain for Hire Dynamics, a warehouse talent recruitment firm with over 300 clients.Turner admits that physical automation is a major investment when it comes to order pick. "This is basically an order picking system that uses robotics to interpret data on the item bought." With this, human talent can concentrate on packaging and shipping the item.

Turner continues, "The manager that we work with said this system had quadrupled its output," It is easier to deliver more products and handle more orders with fewer people. This eliminated the need to recruit and overtime more often, as well as overworking employees which can lead to job satisfaction being lower and higher turnover. "

How Oro helps B2Bs address skills shortages

Oro, a B2B eCommerce vendor is well-versed in the challenges that B2B businesses face each day. While robots will not replace your employees anytime soon, technology can certainly take repetitive and time-consuming tasks off of their hands. Technology can help increase productivity, customer satisfaction, and inventory visibility for managers.

Sean McDonnell is the CEO of TruPar.com, a material handling parts and warehouse supplies distributor.

Sean McDonnell is the CEO of TruPar.com, a material handling parts and warehouse supplies distributor.TruPar has over 8 million SKUs in multiple warehouses and serves more than 45,000 customers. TruPar's sales and marketing team is small despite these large numbers. Because technology makes it easier for customers to access data and use it to personalize their experience. McDonnell says, "If someone is searching for a replacement part to a 1980 Hyster forklift we know which customers are purchasing that forklift."

After implementing a B2B eCommerce system and integrating with the ERP, TruPar relayed real-time inventory and pricing visibility to their customer portal. TruPar's online revenue grew by 25% through digitizing their ordering functions without having to increase their sales or marketing staff.

TruPar's data is spread across the sales, email and website areas so that TruPar can better allocate resources including human resources for maximum value. "About 15% of our customers are never contacted. The remaining 15% will call us with questions. We use customer service experts to make it easy for customers to buy through our website.

Think about your Workforce Needs Now

Manufacturers must innovate their training programs and rethink their compensation and management systems in order to survive and prosper. They also need to think creatively about how they can tap into their labor pool. Your ability to attract top talent is dependent on the workplace dynamics.

Louise Dickmeyer, President at People Driven Performance, says companies can't afford not to pay attention to changing workforce trends. It's time to act immediately if more than 5% are retiring. There are many technologies and tools that can help. Manufacturers should re-educate existing workers, engage with the next generation, as well as leveraging technology to improve their processes and prepare for tomorrow.

Comments

Post a Comment